Plastic

Injection

moulding

Flexible production runs, precise controls, efficient service

Trust your production to Medical Plastics, ISO 9001 and ISO 13485 certified. Our proven team uses the latest plastic injection moulding technology in state-of-the-art facilities.

Flexible production runs, precise controls, efficient service

Trust your production to Medical Plastics, ISO 9001 and ISO 13485 certified. Our proven team uses the latest plastic injection moulding technology in state-of-the-art facilities.

Cutting-edge technology

We pride ourselves on remaining at the forefront of emerging technologies. Our facilities include electric moulding machines of various sizes and capabilities, advanced robotics and a purpose-built clean room. The filtered positive air pressure, temperature and humidity controls ensure we meet the most exacting standards.

Flexible production workflows

Our tight-knit team works around your requirements – even within tight timelines. Our machines range from 15 to 180 tonnes, so we can deliver any size run.

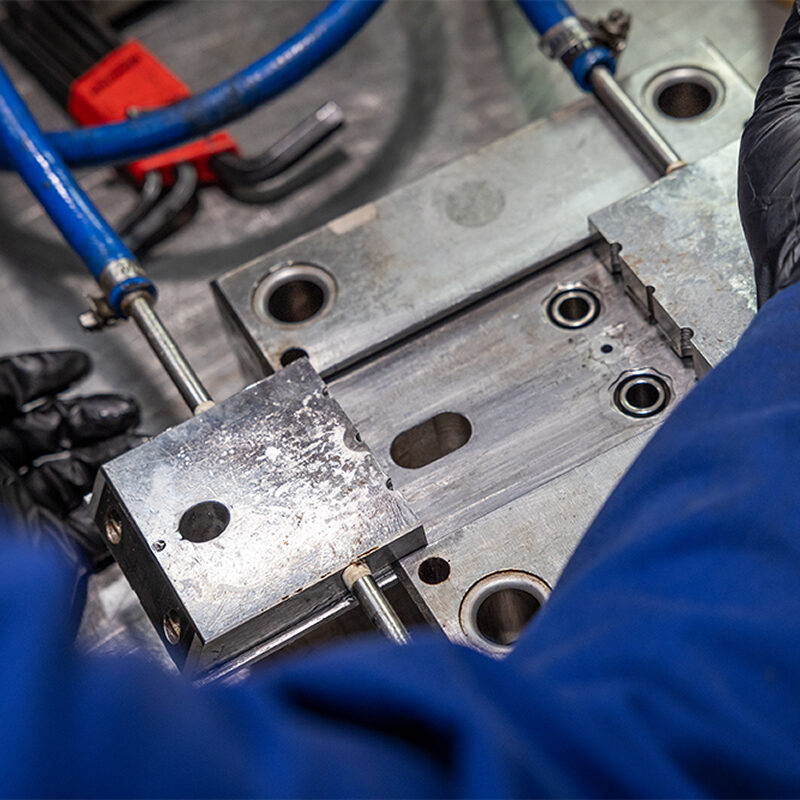

Mould Maintenance

Your moulds are vital to your entire supply chain. Our maintenance solutions and experienced technicians keep your tooling in the best condition, minimising downtime and preventing mould damage or failure. If your moulds need repair or modification, we can also work with our external toolmakers to deliver a timely and cost-effective service.

Wrap-around support

Our excellent industry connections and close working relationships with toolmakers provide customers with the best manufacturing and maintenance support. We can also work with other suppliers to package and dispatch products for retail, export or warehousing.